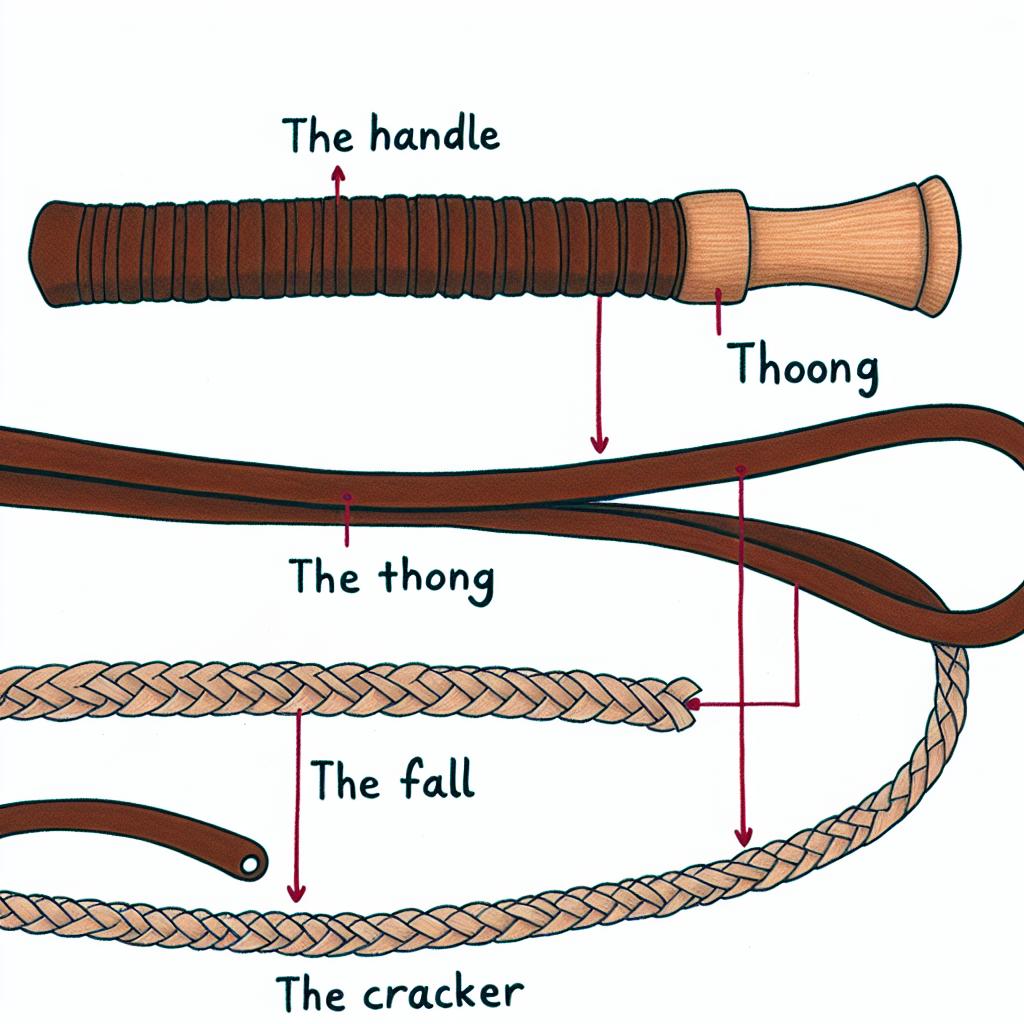

The anatomy of a bullwhip: Handle, thong, fall, and cracker.

The Anatomy of a Bullwhip

A bullwhip is a versatile tool used in various activities, from herding livestock to recreational purposes such as target practice. Understanding its anatomy is essential for proper handling and use. The bullwhip consists of four main parts: the handle, thong, fall, and cracker.

The Handle

The handle is the part of the bullwhip that the operator grips. Typically constructed from sturdy materials like wood or metal, the handle is crucial for control and precision. Its length can vary, but it is generally shorter than the whip’s thong. A well-designed handle often features a wrist loop or a knob to enhance grip and prevent accidental slippage during use. The handle sometimes includes decorative elements such as braided leather or engraved designs to personalize the whip for its owner.

When selecting a handle, consideration of the material is important. Wood provides a natural feel and may be weighted for balance, while metal is often preferred for its durability. The shaping of the handle is also important; ergonomically designed handles can significantly reduce hand fatigue and improve the user’s ability to perform extended tasks.

The Thong

The thong is the longest part of the bullwhip. Consisting of multiple layers of braided leather or other flexible materials, the thong provides the whip with its distinctive cracking sound. The braiding technique is not only decorative but also functional, ensuring that the whip is flexible yet robust. Typically, the thong tapers from the handle to the tip, allowing the energy generated by the handler to travel towards the whip’s end seamlessly.

The thong serves as a conduit for the transfer of energy. Its design reflects centuries of refinement to create a whip that maximizes efficiency and minimizes energy loss. The intricate braiding enhances tensile strength, allowing the whip to endure the rigorous motions it undergoes. Moreover, the tapering of the thong is an engineering marvel, concentrating kinetic energy into a small and powerful endpoint.

The Fall

Positioned between the thong and the cracker is the fall. Often made from a single piece of leather, the fall absorbs much of the stress and wear during use, acting as a replaceable buffer to extend the lifespan of the thong. Its placement ensures that the full force of the whip’s motion culminates in the cracker. The fall’s length and attachment method can vary, but it is usually fixed to the tip of the thong with a knot or lacing.

The fall is a crucial component that takes the majority of the wear and tear, thus protecting the more labor-intensive thong from damage. Understanding various lacing techniques and knots is valuable for those who wish to customize the whip’s performance. Experimenting with different lengths and materials for the fall can vastly impact the usability and sound quality of the whip.

The Cracker

The cracker, also known as the popper, is the thin piece of material at the very end of the bullwhip. Made from lighter materials such as nylon or polyester, the cracker is responsible for the whip’s iconic cracking sound. It is this part of the whip that travels at supersonic speeds, breaking the sound barrier and creating the audible crack. The cracker’s sensitivity to wear means it often requires regular replacement to maintain the whip’s performance.

Though tiny, the cracker holds substantial significance. It plays a critical role in creating the sound, acting as a tip that breaks the sound barrier. The balance between the weight and material of the cracker must be optimally tuned to produce the desired loudness and sharpness. Regular replacement of the cracker not only sustains performance but also allows for experimentation with different designs and materials for diverse sound effects.

Understanding and Maintenance

Proper care of a bullwhip involves regular inspection and maintenance of its components. The handle should be checked for structural integrity, while the thong may need conditioning to maintain flexibility and prevent drying. Similarly, inspecting the fall for signs of wear and replacing the cracker when necessary can prolong the whip’s usability. For those interested in learning more about bullwhip care and techniques, there are numerous resources and communities online that offer guidance and support.

Maintenance begins with understanding the characteristics of the materials involved, such as leather, which requires conditioning to prevent cracking and dryness. Applying leather care products can help in retaining suppleness. Metal parts, if present in the handle, should be inspected for rust or corrosion and cleaned accordingly.

The replacement of the fall and cracker as per usage intensity keeps the whip in peak condition. Participating in workshops or learning from seasoned handlers can provide practical insights into whip care. Additionally, joining communities devoted to whip utilities can enhance one’s appreciation for the craftsmanship involved.

Understanding the detailed construction of each component and dedicating time to maintenance ensures that the whip functions optimally and lasts longer. Incorporating traditional and modern techniques in crafting these elements can also cater to specific needs, varying from collectors desiring aesthetic finesse to professionals requiring functional precision. In mastering the anatomy of a bullwhip, one not only gains technical expertise but also a profound respect for this multifunctional tool.