The materials used to make bullwhips.

Bullwhips and Their Construction Materials

Bullwhips, recognized widely for their use in herding livestock, performance arts, and as skill-based collectibles, have a rich history that spans cultures and centuries. Their construction is a skilled craft, reliant on quality materials to ensure performance and longevity. The variety of materials used in making bullwhips speaks volumes about the cultures that utilized them and the environments they were adapted for. Understanding these materials offers insight into the nuanced craft of bullwhip making, delineating why certain materials are chosen over others.

Traditional Materials Used in Bullwhip Creation

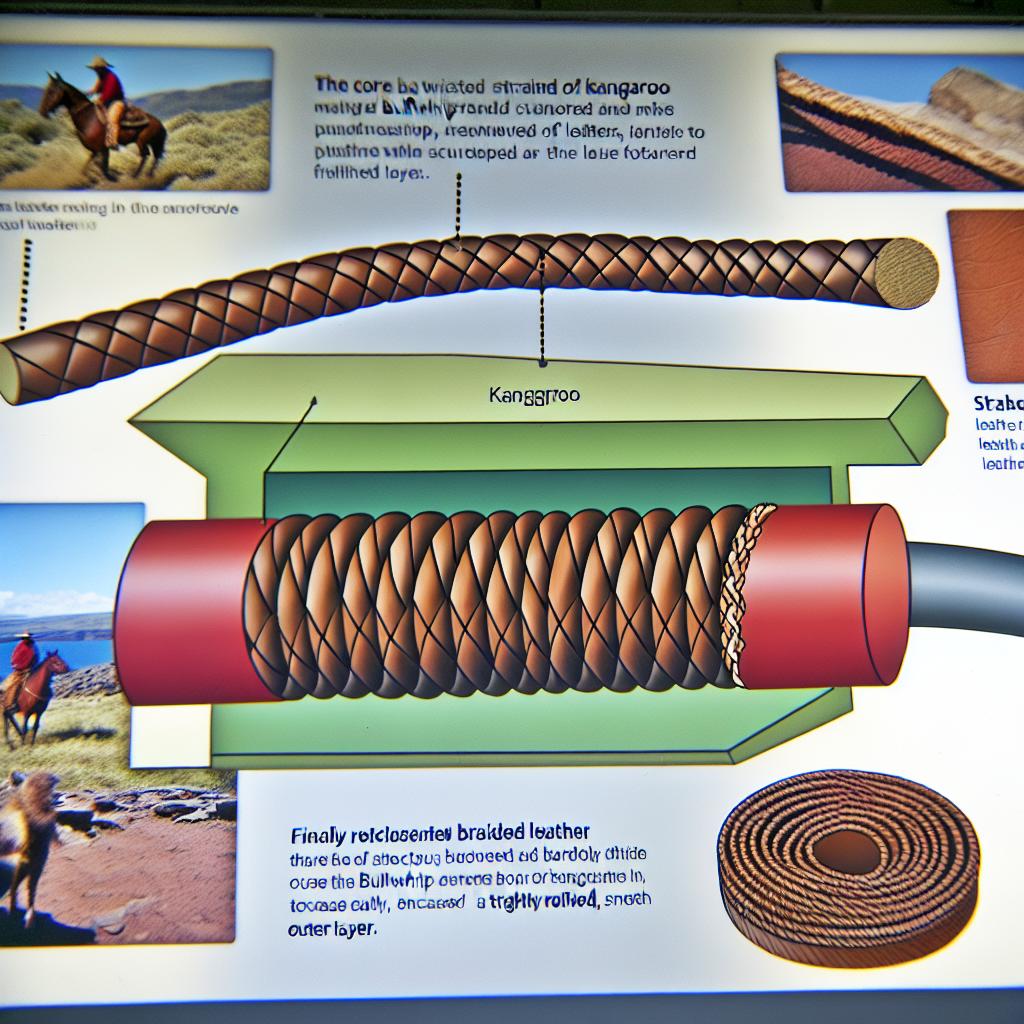

Throughout history, leather has been the quintessential material for bullwhip creation. Among the different types of leather used, kangaroo leather stands out predominantly. Valued for its distinctive attributes, kangaroo leather is recognized for its exceptional strength, light weight, and flexibility. These characteristics are vital in producing a whip that is not only durable but also has the desired precision for effective use. The ability of kangaroo leather to be split into very fine layers while maintaining its robustness allows artisans to create intricately braided whips that offer a smooth and fluid action—key aspects for both performance and functionality.

Despite the premium features of kangaroo leather, it is not the sole material used in whip making. Another commonly used leather is cowhide leather. While cowhide does not possess the suppleness of kangaroo leather, it continues to be a popular choice due largely to its durability. Cowhide provides satisfactory performance, making it suitable for both practice sessions and casual uses where the whip is not subjected to extreme stress. Furthermore, cowhide is more readily available and cost-effective compared to kangaroo leather, allowing wider access for enthusiasts and hobbyists alike.

Synthetic Alternatives

In recent years, innovations have brought synthetic materials to the fore in the domain of bullwhip creation. These materials, which include synthetic fibers such as nylon, offer attributes similar to leather. Nylon, for instance, is celebrated for its resistance against harsh weather conditions, negating concerns about moisture and other environmental factors that may affect leather whips adversely. An additional advantage of synthetic whips is their reduced maintenance compared to leather ones, making them appealing for users who prefer less upkeep.

Another element that makes synthetic bullwhips favorable is their affordability. They are typically less expensive than their leather counterparts, which can be conducive for beginners or for situations which potentially involve extensive wear and tear. This accessibility does not indicate subpar performance; on the contrary, synthetic whips are often praised for their consistency and longevity under varied conditions, making them a practical choice for many.

Additional Bullwhip Components

Beyond the main body of the bullwhip, which may be leather or synthetic, several additional components are crucial to the whip’s performance. One such component is the core, which serves as the backbone or internal structure of the whip. Traditional bullwhips use cores crafted from twisted leather, adding to the whip’s weight and balance. Conversely, modern whips may utilize tightly braided synthetic cords, providing resilience and the desired weight distribution for accurate handling.

Another significant component is the handle. Typically rigid, the material of the handle significantly influences the grip and overall balance of the whip. Common materials for the handle include wood or plastic, as both offer durability and comfort in hand. The craftsmanship involved in the handle plays a critical role in the whip’s handling dynamics, often determined by the whip maker’s expertise and attention to detail.

Finally, no bullwhip is complete without the fall and cracker. These elements, located at the extremity of the whip, are essential for achieving the whip’s iconic crack—an auditory indication of the whip breaking the sound barrier. Over time, both the fall and cracker may undergo wear and require periodic replacement to ensure the whip maintains its peak performance and safety.

Conclusion

In conclusion, the art of bullwhip making is a sophisticated craft that revolves around the deliberate selection of materials. Whether opting for the timeless traditional allure of leather or the innovative durability of synthetic alternatives, the choice of material significantly influences the whip’s characteristics. Each component in the whip’s construction, from the core to the cracker, serves a purpose that is reflected in the whip’s overall performance and usability. For enthusiasts interested in a deeper exploration of crafting techniques and material properties, a wealth of specialized resources is available, offering insights into both the historical craftsmanship and contemporary advancements in the practice of whip-making.